Azo dyes are the most numerous and most significant group of organic dyes. Although many of them have been shown to be carcinogenic or cause urticaria or allergies, they are still used to dye everything from textiles to plastics or paper. Over 70,000 tonnes are consumed annually in the world, much of it in China.

However, around 15 to 20 per cent leak into the environment during production or dying alone, creating massive contamination of surface or groundwater and soil. This is the initial state that scientists from the Institute of Chemistry and Biochemistry are trying to change.

In the framework of the European Commission call H2020, which is the main instrument for financing research, technological development and innovation for the period 2014-2020, the Brno Institute of Chemistry and Biochemistry has been the only Czech entity involved in the international project GREENER (InteGRated systems for Effective ENvironmEntal Remediation). In addition to 22 scientific institutions and companies from Germany, Great Britain, Spain, Belgium or Italy, Chinese partners also participate. The first research results should be known by the end of 2020, and the whole project will continue until 2023. The broad-based project focuses on the development and practical application of environmentally sustainable, efficient and low-cost solutions to environmental bioremediation, in layman terms, decomposition of toxic substances to less toxic or non-toxic ones.

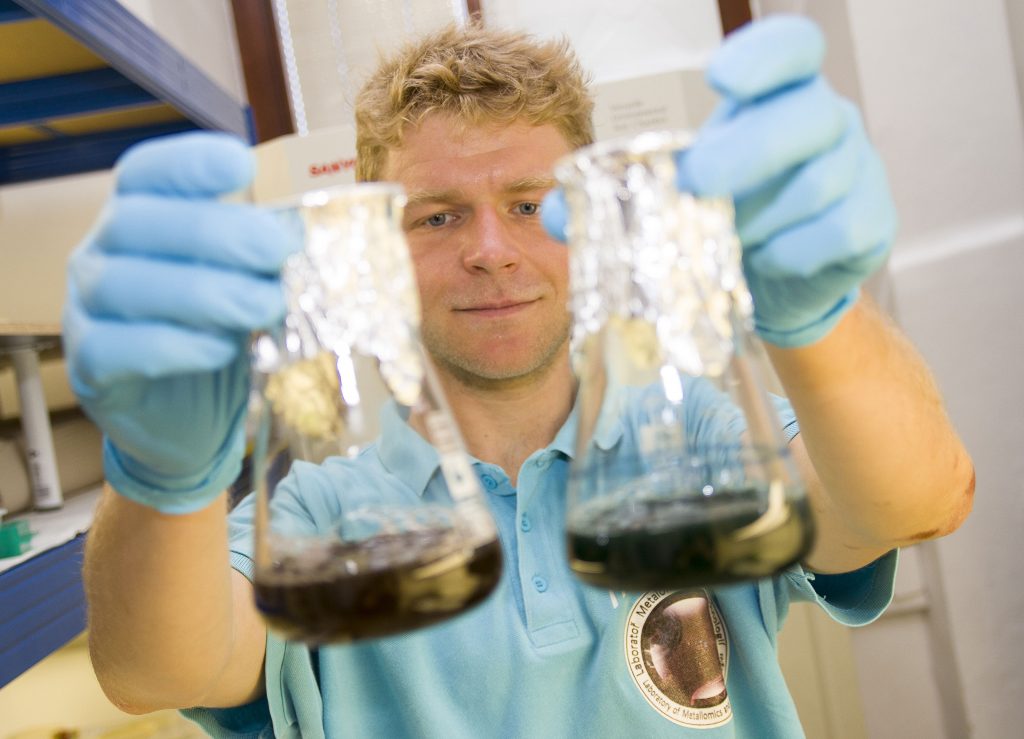

In Brno, this is done using microalgae. “These are unicellular, photosynthetically active microorganisms with great genetic variability. There are tens of thousands of species that can survive in a variety of conditions – in humid, dry, low and high temperatures, or in soil salinized or contaminated to various extents, and we want to take advantage of these properties,” outlines the head of the plant metabolomics and epigenetics laboratory Ing. Dalibor Húska, Ph.D.

Researchers use sterile microalgae from genetic banks and test different types of azo dyes to determine which microalgae can absorb them best. “That is, of course, moving the problem from soil or water to the plant. Consequently, the microalgae must be harvested and the problem of what to do with them, whether to burn or store them, has to be solved. Therefore, the ideal result should be to find microalgae that can biodegrade azo dyes, decompose them into non-toxic or less toxic substances,” adds Húska. Phytoremediation (removal of harmful substances through microalgae) could also be used for heavy metals such as cadmium or lead.

After the initial, lab phase, in which researchers will test the interaction of sterile samples of microalgae and conventional azo dyes, the practical phase will follow. “We will have authentic samples of contaminated soil from our German partners. It contains a number of other substances such as pesticides, water, bacteria and other organisms. Therefore, we will have to optimize and adapt our findings to make them usable in practice,” says Húska.

Another part of the Brno research was the creation or adaptation of analytical tools for the project. “This is a complex package of analytical methods and we have introduced more specific numbers to biology. Using mass spectrometry or a fluorescence in vivo imager, we are able to monitor and measure the state of microalgae, decreasing the amount of azo dyes and the overall efficiency of biodegradation from the beginning to the end,” explains doc. Mgr. Markéta Vaculovičová, the head of the research group for bio nano-analysis and genetic engineering.

Azo dyes are relatively stable compounds and even sewage treatment plants usually cannot cope with them. These substances are, therefore, returned to people, for example, in the form of drinking water. For that reason, another aim of the researchers at the Institute of Chemistry and Biochemistry is to put the acquired knowledge into practice. “We want to create a methodology that is easy to apply even in sewage treatment plants. For example, by creating a bioreactor that would be connected to the water circuit of the particular sewage treatment plant or factory. Polluted water would go through this bioreactor to be decontaminated by microalgae,” explains Húska.